At Masterpiece, we pride ourselves on our product and invest heavily in the best state-of-the-art equipment available to the industry in order to ensure that we produce not only the most beautiful windows in the market but also the highest quality. Utilizing the best assembly technologies guarantees the craftsmanship of our product, speeds up the process of construction of our windows, and allows us to offer them at more affordable prices than other leaded glass plants.

Quality leaded glass windows and poorly constructed leaded glass windows comparison

Bad solder joint.

This window made by another leaded glass company has been poorly soldered at the joints, resulting in a weak window that is visually unpleasing. Masterpiece uses traditinal techniqes to ensure straight lead lines and strong solder joints, making sure they are consistent throughout the window and not oversized.

OTHER:

OURS:

Bad Alignment and Bad Soldering

This window made by another leaded glass company was unfortunately installed into a model home in Southern California. There are several problems with this window. The lead lines are crooked and very poorly soldered. Mass amounts of solder have been used here to fill in mistakes. Windows like this one will almost always leak rainwater into the home, causing damage to the interior of the home. When given the choice between this poorly made leaded window and normal clear glass, the homeowner would be much better off with the latter.

OTHER:

OURS:

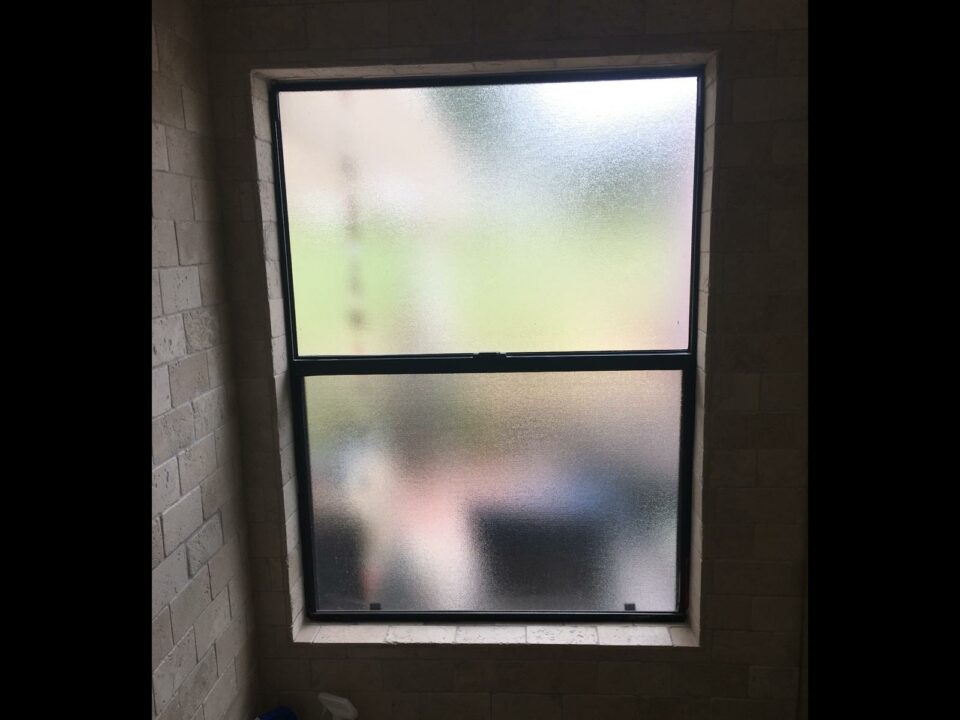

Corrosion and Leaks

You can see the corrosion beginning at the edges of the lead in this window (left). This is likely due to poor curation of the window after cementing the lead lines. This is also a sure sign that the window will leak into the home when it rains and possibly do damage to the interior walls of the home.

Masterpiece leaded windows are built triple-paned and sealed to ensure excellent performance in all weather conditions. Our window products are superior in design and performance.

OTHER:

OURS:

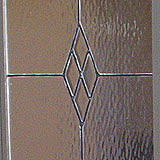

Filling Mistakes With Solder

Overuse of solder in connecting leaded windows are not only unsightly, but also can often cause a window to crack once installed. Large amounts of solder is often incorrectly used to mask mistakes in glass alignment, or hide chips in the glass. All windows need to be able to evenly flex when pushed by wind or rain. When there are uneven pressure spots in the window, like this one, the window is more likely to crack or break.

OTHER:

OURS:

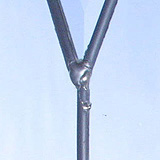

Too Much Solder

This is a good example of poor craftsmanship. You can see the large, unfavorable globule of solder connecting the lead lines. This is typical of leaded windows being manufactured by untrained workers and creates an undesireable look when the window is completed.

Masterpiece leaded windows has pioneered many of the methods used in today’s leaded glass windows. Making small, uniform solder joints is essential to every window we build.

OTHER:

OURS: